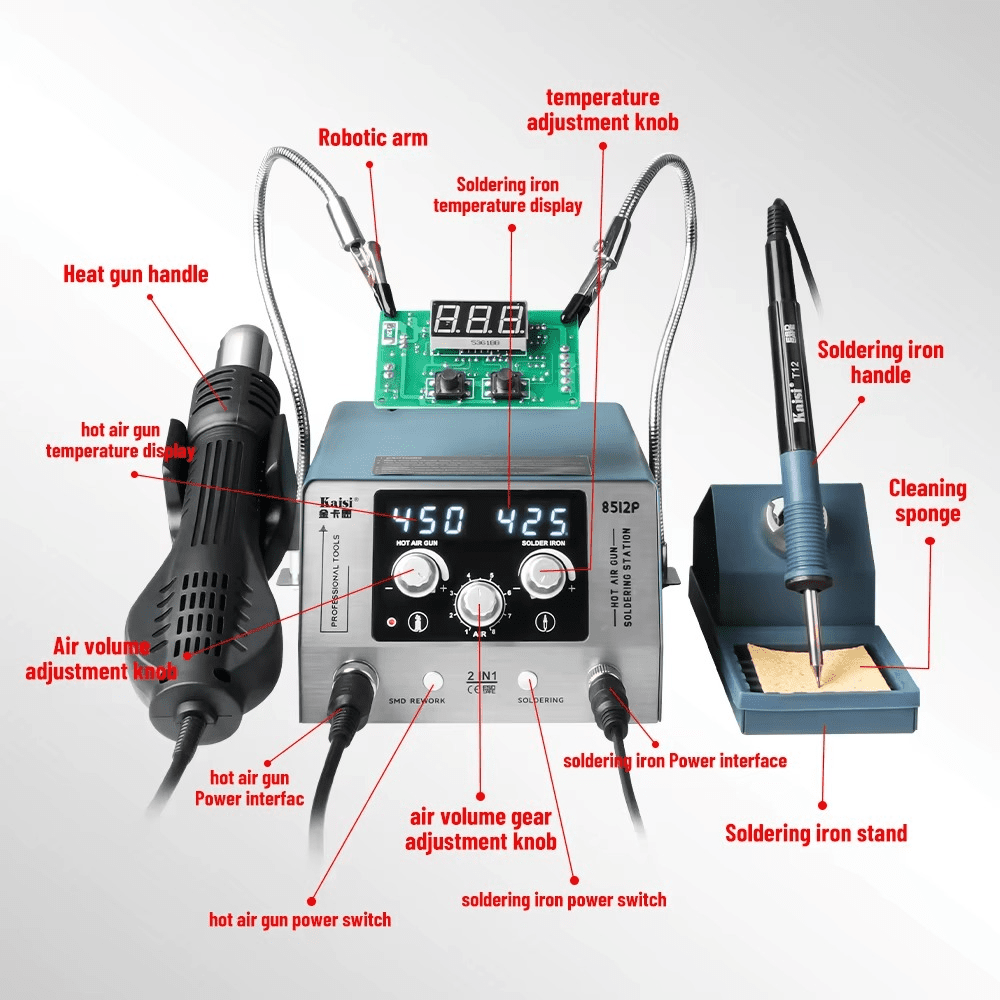

Need professional 2-in-1 capability with proper T12 performance? The Kaisi 8512P delivers 700W of power combining a T12 soldering iron with a hot air gun—not the outdated 936 handles found in budget stations. The ceramic heater maintains ±2°C temperature stability while the customisable sleep mode (1-30 minutes) adapts to your workflow.

Both tools display real-time temperature on dedicated LEDs. Temperature compensation keeps your tip at the set point throughout soldering. This is serious 2-in-1 capability for repair techs who need efficiency, accuracy, and reliability.

At a Glance

| Hot Air Gun | T12 Soldering Iron |

|---|---|

| 100°C – 450°C range | 200°C – 500°C range |

| 120 L/min max airflow | T12 cartridge system |

| LED temperature display | LED temperature display |

| Ceramic heating element | Temperature compensation |

| Microcomputer control | Auto-sleep with metal ring |

✓ 700W maximum power ✓ ±2°C temperature stability ✓ ESD-safe soldering iron design ✓ Customisable sleep time (1-30 min) ✓ 4 T12 tips + 5 air gun nozzles included ✓ Spare heating core included ✓ Universal voltage (110V/220V)

T12 Handle: Professional Performance

Most budget 2-in-1 stations use 936-style handles—older technology with poor temperature accuracy. Set 350°C on a 936 and actual tip temperature might reach 450°C. The Kaisi 8512P uses the superior T12 system instead.

| 936 Handle | T12 Handle |

|---|---|

| Large temperature errors | ±2°C stability (calibrated) |

| Guesswork required | Accurate, predictable heat |

| Slower thermal response | Fast heating and recovery |

| Shorter tip lifespan | Extended tip life |

| Basic design | Integrated heater/sensor |

Why T12 matters:

→ Heater and sensor inside the cartridge → Real temperature matches set temperature → Calibration achieves very small errors → Professional accuracy for proper repair work

Maintenance work isn’t child’s play. Temperature judgment should be based on actual measurement, not guesswork.

Temperature Compensation

Heat flows from your tip to your work. Without compensation, tip temperature drops during soldering. The Kaisi 8512P compensates automatically:

→ Monitors tip temperature continuously → Detects heat loss during soldering → Increases power delivery instantly → Maintains set temperature throughout the joint

Set 350°C → Get 350°C—throughout every joint, not just at idle.

Customisable Sleep Mode

The T12 handle includes a sleeping metal ring. Place it in the stand and sleep mode activates—but you control the timing.

Customisable from 1 to 30 minutes:

| Setting | Best For |

|---|---|

| 1-5 min | Fast-paced work, quick protection |

| 10-15 min | Standard repair workflow |

| 20-30 min | Extended tasks, fewer interruptions |

Set the sleep time that matches your work habits. The machine adapts to you, not the other way around.

±2°C Temperature Stability

The ceramic heater delivers consistent, stable heat:

→ Maintains temperature within ±2°C → No fluctuation during operation → Reliable results on every joint → Professional-grade accuracy

Ceramic heating elements provide even heat distribution and long operational life.

Dual LED Temperature Display

Both tools show real-time temperature on dedicated LED displays:

Hot Air Gun Display: → Set temperature → Actual temperature → Operating status

Soldering Iron Display: → Set temperature → Actual temperature → Sleep/active status

Monitor both tools simultaneously. Know exactly what’s happening with each tool at a glance.

Microcomputer Temperature Control

The Kaisi 8512P uses microcomputer control for precise temperature management:

→ Accurate temperature regulation → Stable output regardless of conditions → Fast response to thermal demand → Professional-grade control system

Better control means better results on every repair.

Hot Air Station Performance

The hot air gun delivers 120 L/min maximum airflow with temperature range from 100°C to 450°C:

Low temperature (100°C-200°C): → Heat shrink tubing → Preheating → Gentle warming

Medium temperature (200°C-350°C): → Leaded solder reflow → General SMD work → Component removal

High temperature (350°C-450°C): → Lead-free solder work → BGA rework → Stubborn joints

ESD-Safe Design

The soldering iron features ESD-safe construction:

→ Protects sensitive electronics → Safe for CMOS and IC work → Proper grounding design → Professional workshop standard

Work confidently on modern electronics with proper static protection.

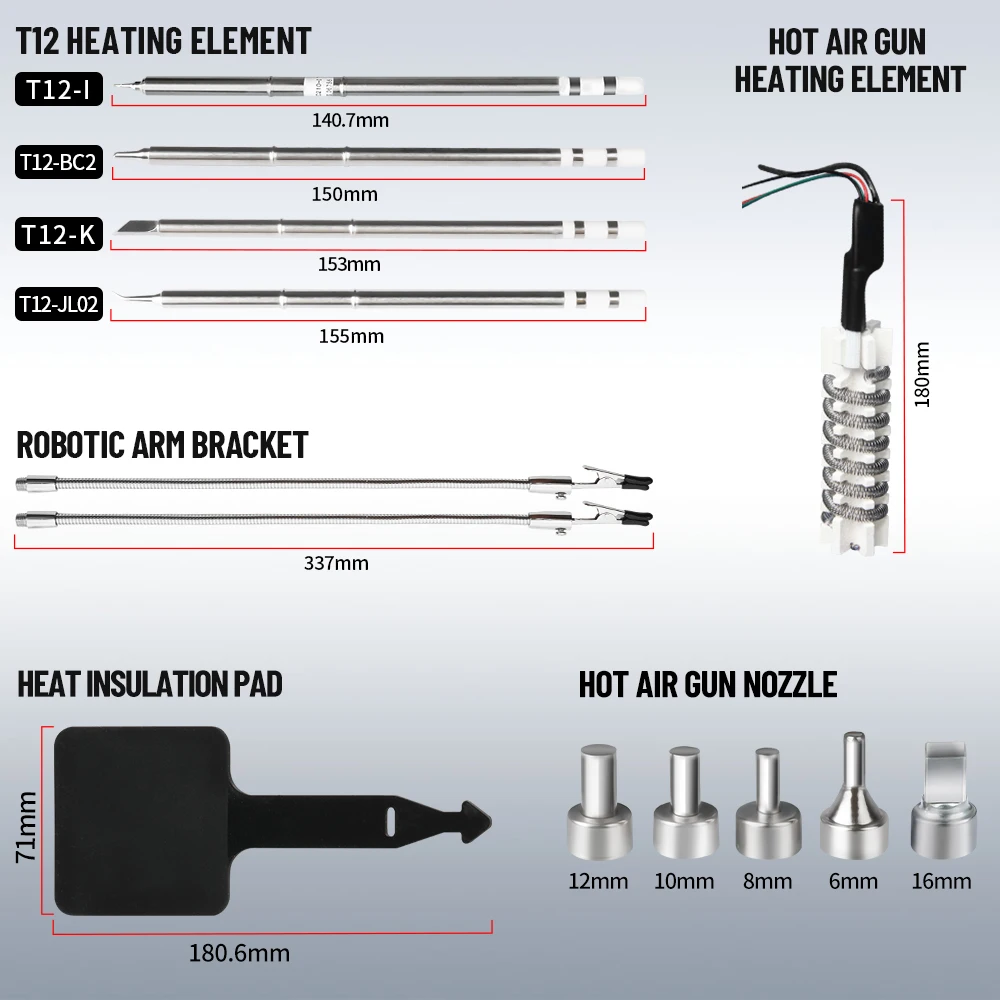

Included T12 Tips

Four T12 cartridges cover varied soldering tasks:

| Cartridge | Shape | Best For |

|---|---|---|

| T12-ILS | Conical bent | Fine-pitch work, angled access |

| T12-JL02 | Bent tip | Drag soldering, tight spaces |

| T12-K | Knife/Blade | SMD work, solder shaping |

| T12-BC2 | Bevel/Chisel | General purpose, heat transfer |

Complete tip set for varied work—no additional purchases needed to start.

Included Air Gun Nozzles

Five nozzles for different applications:

| Size | Best For |

|---|---|

| 6mm | Small components, concentrated heat |

| 8mm | Fine-pitch SMD, precision work |

| 10mm | Standard packages, general use |

| 12mm | Larger components, wider coverage |

| 16mm square | BGA packages, even heat distribution |

Complete nozzle set covers most rework requirements.

Spare Heating Core Included

The package includes an 858D heating core as a spare:

→ Ready when you need it → No downtime hunting for parts → Extended station lifespan → Professional preparedness

One less thing to worry about.

New Tip Break-In Procedure

When using a new T12 tip for the first time:

- Insert the new tip

- Heat for 5 minutes before starting work

- This improves temperature stability

- Extends overall tip life

Proper break-in ensures optimal performance from every cartridge.

What You Can Repair and Build

Phone and Tablet Repair Hot air for shield removal and IC extraction. T12 iron for connector work and touch-up. Both tools ready simultaneously.

Console Repairs Hot air handles component removal. T12 iron reinstalls with precision. Temperature compensation ensures reliable joints.

SMD Rework Air gun handles SOIC, CHIP, QFP, PLCC, and BGA packages. T12 iron completes rework with accurate heat.

Beyond Soldering The hot air gun handles multiple applications:

| Application | Use |

|---|---|

| Heat shrink | Low temp, controlled airflow |

| Paint removal | High temp application |

| Adhesive removal | Medium temp, focused heat |

| De-icing | Gentle warming |

| Preheating | Board preparation |

| Glue work | Controlled heating |

Metal Bracket Protection

The included metal bracket:

→ Protects iron from flammable materials → Secure storage for hot tools → Safe workspace organisation → Professional setup

Proper protection for professional work.

Temperature Calibration

For optimal accuracy, calibrate the station:

→ Use a temperature tester (S-191 calibrator recommended) → Verify actual tip temperature → Adjust calibration as needed → Achieve very small temperature errors

Professional repair work requires accurate temperature verification, not guesswork.

Technical Specifications

| Specification | Value |

|---|---|

| Model | Kaisi 8512P |

| Maximum Power | 700W |

| Input Voltage | AC 220V / AC 110V |

| Frequency | 50Hz |

| Temperature Stability | ±2°C |

Hot Air Station:

| Specification | Value |

|---|---|

| Temperature Range | 100°C – 450°C |

| Maximum Airflow | 120 L/min |

| Heater Material | Ceramic |

| Display | LED real-time |

Soldering Iron:

| Specification | Value |

|---|---|

| Temperature Range | 200°C – 500°C |

| Handle Type | T12 |

| ESD Design | Yes |

| Sleep Mode | 1-30 minutes (customisable) |

| Temperature Compensation | Automatic |

| Display | LED real-time |

What’s in the Box

| Quantity | Item |

|---|---|

| 1x | Kaisi 8512P base station |

| 1x | Hot air gun with handle |

| 1x | T12 soldering iron handle |

| 1x | T12-ILS cartridge (conical bent) |

| 1x | T12-JL02 cartridge (bent tip) |

| 1x | T12-K cartridge (knife) |

| 1x | T12-BC2 cartridge (bevel) |

| 1x | Air gun nozzle 6mm |

| 1x | Air gun nozzle 8mm |

| 1x | Air gun nozzle 10mm |

| 1x | Air gun nozzle 12mm |

| 1x | Square air gun nozzle 16mm |

| 1x | 858D heating core (spare) |

| 1x | Metal bracket/stand |

| 1x | Power cable |

| 1x | User manual |

Complete kit: 4 T12 tips + 5 nozzles + spare heating core = ready for serious work.

T12 Cartridge Compatibility

The Kaisi 8512P uses standard T12 cartridges. Expand your tip selection with:

→ Various chisel sizes → Specialty shapes → Fine-pitch profiles → High-thermal-mass options

Wide availability from multiple manufacturers.

Ideal For

| User | Why 8512P Works |

|---|---|

| Phone repair techs | T12 precision, dual tool capability |

| Console repair shops | Hot air + accurate soldering |

| SMD rework | Stable temperature, comprehensive kit |

| Small workshops | Space-efficient 2-in-1 design |

| Quality-focused repair | ±2°C stability, proper calibration |

| Professional upgraders | T12 performance, complete accessories |

What Makers Are Saying

“The customisable sleep time is perfect—I set it to 5 minutes for fast-paced phone work. Temperature stability is noticeably better than my old 936-based station. The included spare heating core shows they understand repair shop needs.”

“Finally accurate temperature on a 2-in-1 station. Calibrated it with my tester and it’s spot-on. The T12 tips heat up fast and the compensation keeps temperature steady while I’m actually soldering. That’s what matters.”